Making of a Rapier

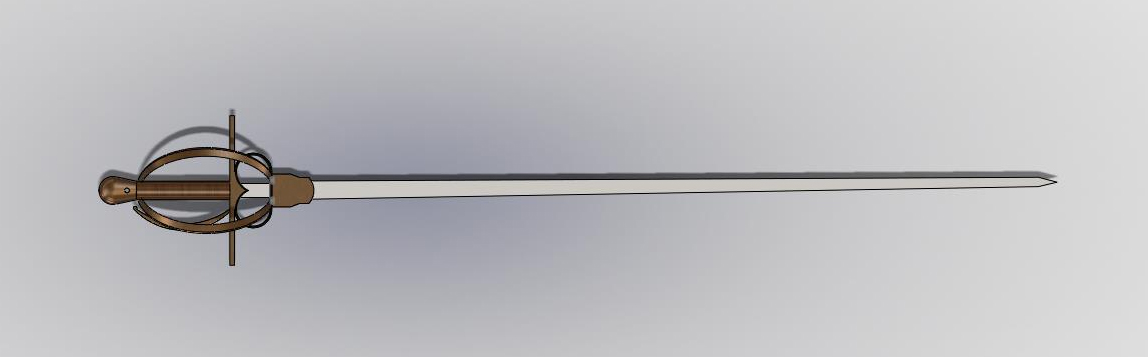

The image above is a CAD model created to show the rough design for the rapier replica. It is made to resemble rapiers at the time. The actual replica changed due to manufacturing and time constraints.

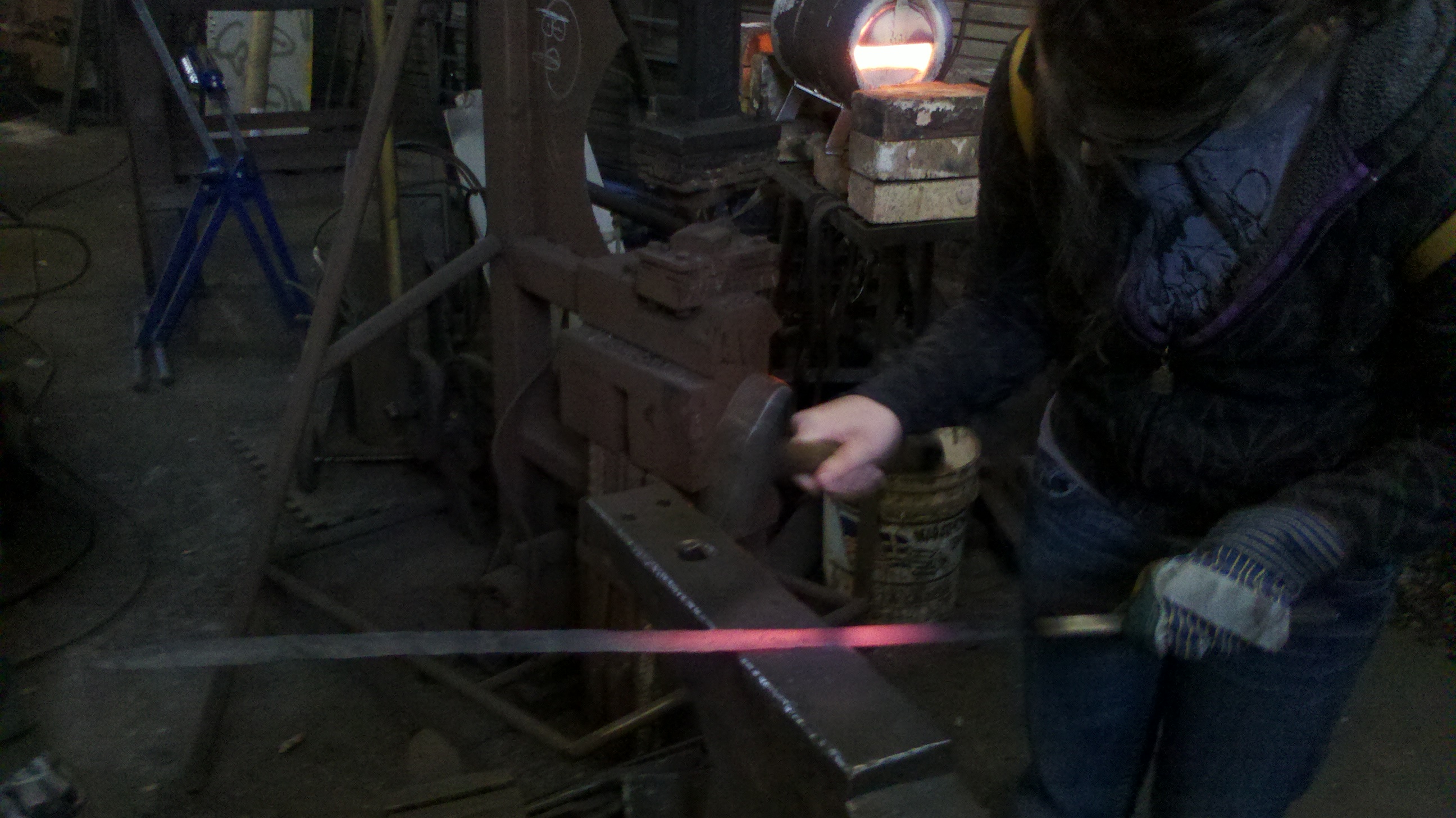

The blade was made using 4140 steel, tempered with hammer and anvil, and allowed to cool in open air. The process causes the steel to loose the shine it had in it's original bar shape.

The tip of the blade was made by pre-cutting the angle near the top, and using the hammer to flatten the sides. This allowed the process of the tip to avoid the issue of folding the metal over wrong and potentially weakening it.

1 foot of steel was left unhammered near the end, to attach the pommel, guard, and leather for the handle.

The final state of the blade was polished, and when compared to the unpolished version (above), made cleaner and less rusted.

The crossguard was made of a thinner bar of copper, and formed by using an Acetylene Torch to quickly bend the metal without it melting. The ends of the piece used as the crossguard were also hammered flatter, to form a decorative loop.

The finished crossguard is designed to be able to act as a grip when on the finished rapier. The large loops are held in the hand, with the blade passing through the center, from bottom to top.

The pommel is made using scrap iron shaped into the pictured form. The piece is not made to be very elaborate, as it's only purpose is to be a counterweight to the rest of the blade, and is covered up in the finished design.

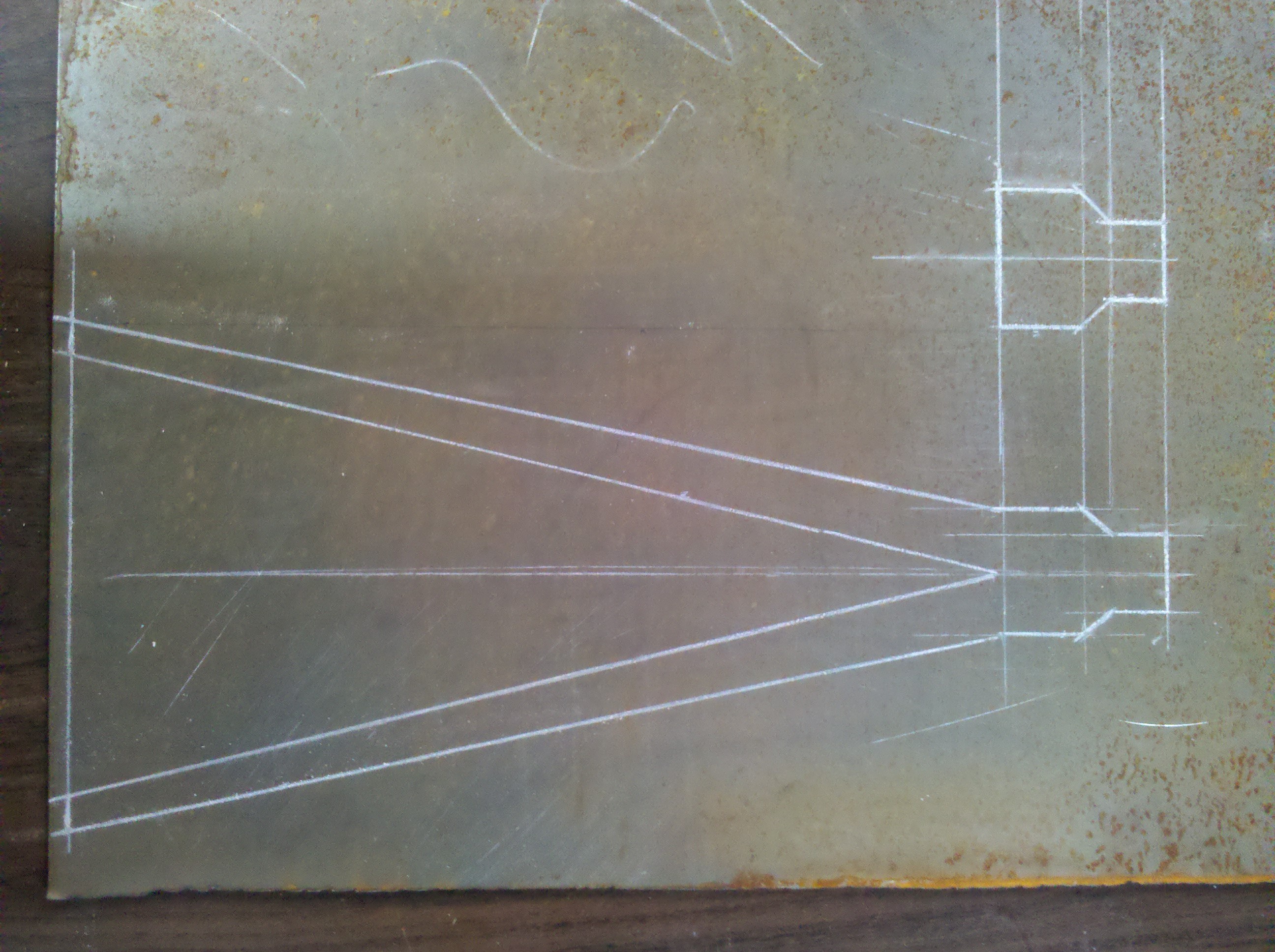

The hilt of the blade, much like the rapiers being replicated, had a stylistic hilt adorning the blade. The design chosen was that of a Goat's head & horns, cut from sheet metal.

The rapier's total parts consist of: the blade, crossguard, 2 hilt pieces (upper and lower halves), the pommel, and leather bindings (not pictured). The metal pieces are either welded in, or in the case of the copper crossguard, bound in place.